IF YOU WANT TO HAVE THE SURFACES OF YOUR WORKPIECES TREATED IN SMALL OR LARGER QUANTITIES, WE WILL BE HAPPY TO DO THAT FOR YOU IN CONTRACT WORK.

Surface treatment in the following areas:

- Plastics production

- Elastomer production

- Die casting molds

- Stamping technology

- Forming technology

- EDM

- HSM / HSC – High Speed Milling / Cutting

- CIM / MIM – Ceramic / Metal Injection Molding

- Rapid Prototyping

- Laser beam melting

- Medical technology

- PVD-CVD coating

- Extrusion

- Food industry

- Plastics / processing

- Silicone / processing

Micro blasting in the following areas:

- Structuring according to VDI

- Demoulding blasting

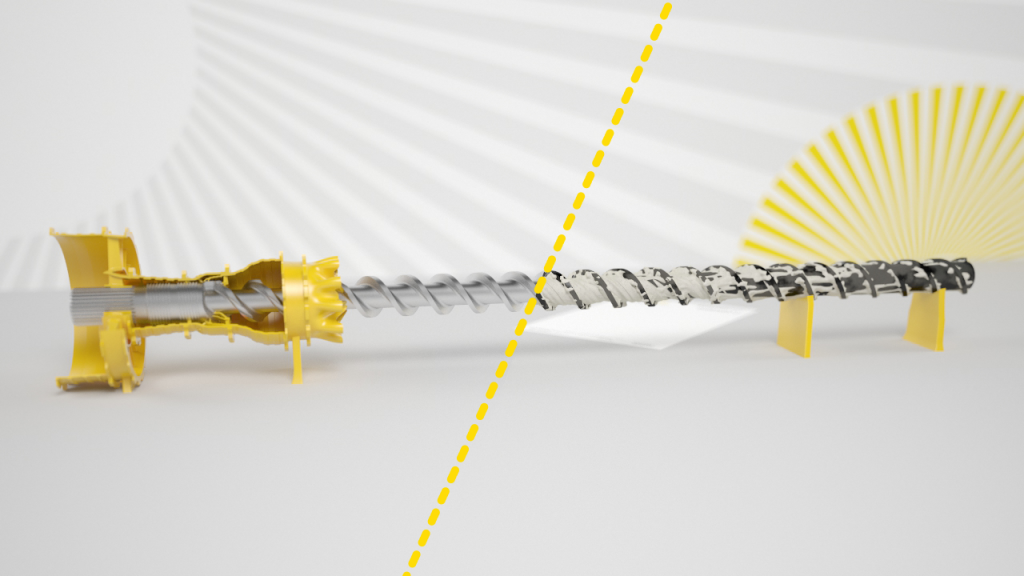

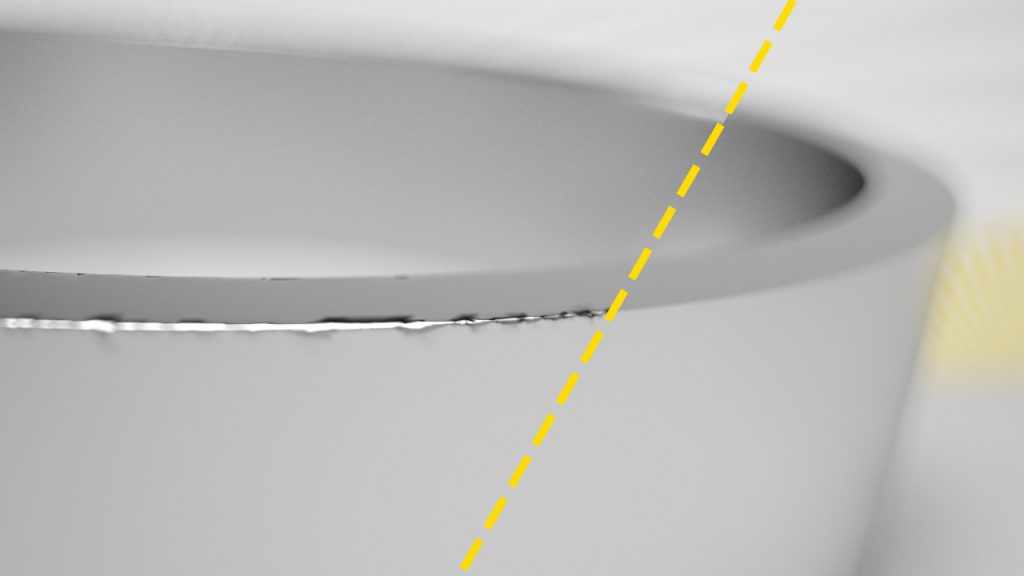

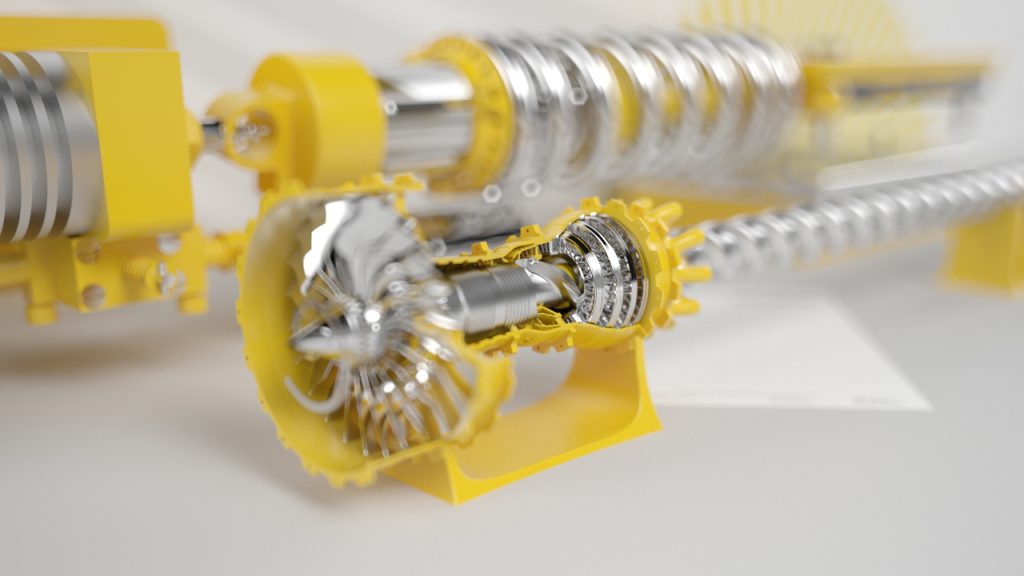

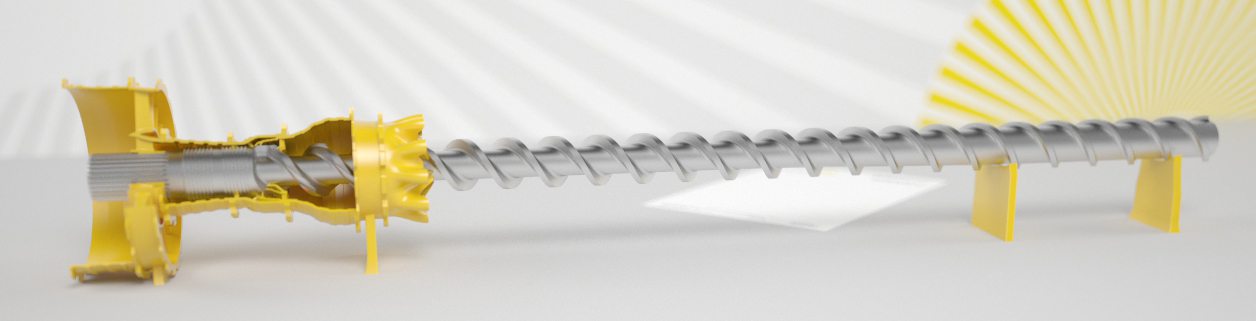

- Cleaning blasting (soft blasting) of extruder screws and molds

- Deburring of components for smaller batch sizes

- Shot peening of highly stressed components

- Polishing

In contract work we treat your workpiece as desired.

We offer individual advice.

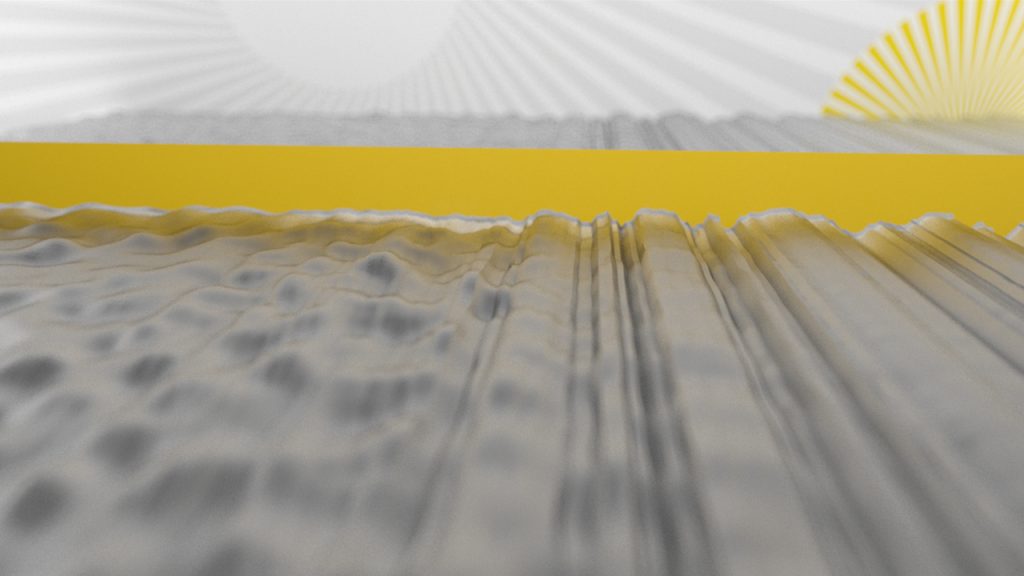

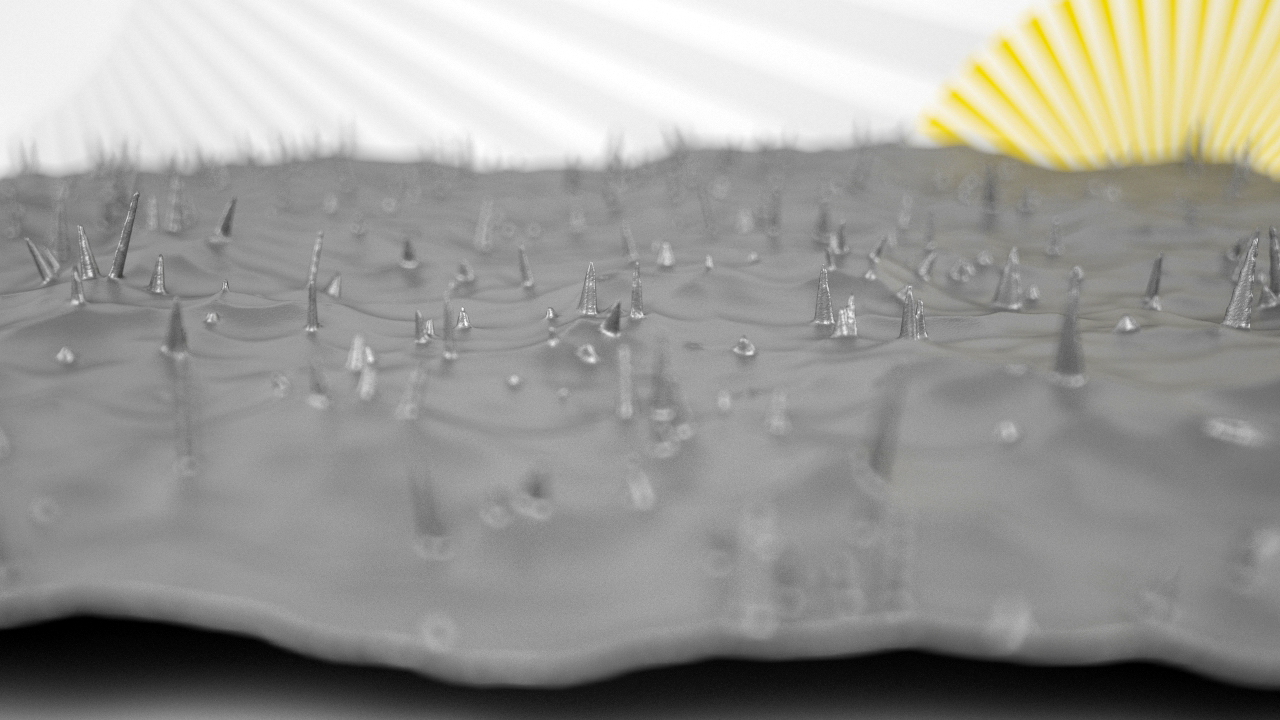

STRUCTURE BLASTING

We optimize the demoldability, the degree of gloss, the roughness, a desired adhesion or another surface property for you.

Application areas:

- Structuring according to VDI

- Die casting

Wir optimieren für Sie die Entformbarkeit, den Glanzgrad, die Rauheit, eine gewünschte Haftung oder eine andere Oberflächen-Eigenschaft.

Anwendungsgebiete:

- Strukturieren nach VDI

- Druckguss

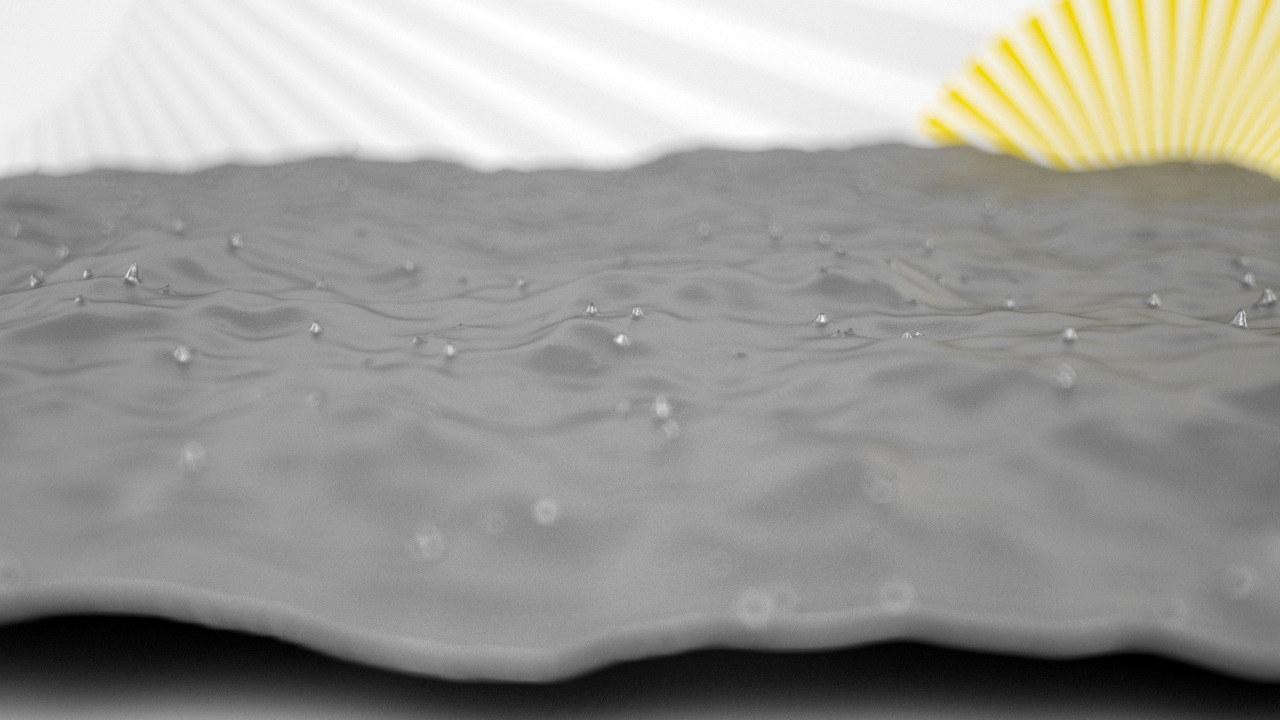

POLISH BLASTING

After a coating such as CVD, PVD, DLC or others, we optimize your components: high gloss, non-stick or better sliding properties. Precision polishing on stamping, cutting and forming tools.

Application areas:

- Pharmaindustry

- Medical technology

- Stamping technology

Example of contract work: Cleaning a plastic granulate screw conveyor with soft jets & 2-stage optimization